Why Hollow-Shaft Encoders Are Chosen

Hollow-shaft SSI absolute encoders are primarily selected when direct shaft mounting is required, or when installation space is limited.

Unlike solid-shaft designs, hollow-shaft configurations allow the encoder to be placed over an existing machine shaft without additional couplings, reducing mechanical components and assembly complexity.

From an engineering perspective, this selection is driven not by size or resolution, but by mechanical integration constraints, alignment accuracy, and shaft compatibility.

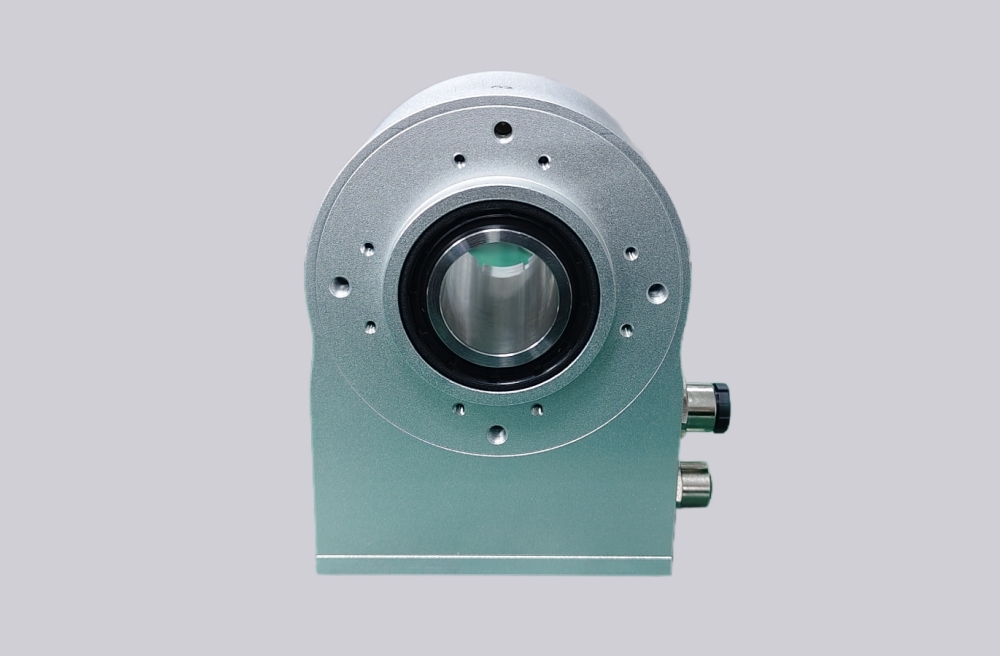

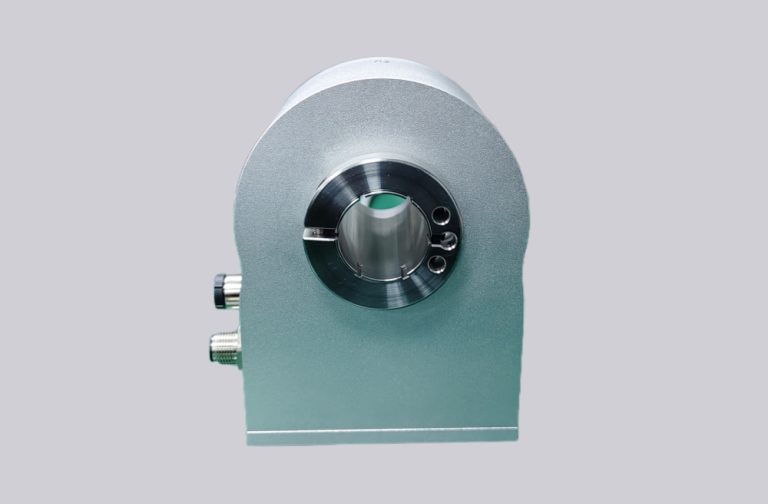

Mechanical Concept of Hollow-Shaft Encoders

Hollow-shaft encoders typically feature:

- Blind hollow shafts for clamping onto solid shafts

- Compact cylindrical housing to fit over existing shafts

- Flexible mounting options, including face and clamping flanges

These design characteristics allow the encoder to directly interface with rotating machinery while maintaining absolute position feedback accuracy.

In practice, the hollow-shaft configuration provides a reliable mechanical connection with minimal installation effort.

Shaft Mounting and Alignment Considerations

Direct-shaft mounting introduces specific alignment requirements:

- Shaft concentricity and surface finish affect signal accuracy

- Clamping force and axial positioning must be controlled to avoid mechanical stress

- Flexible couplings are generally unnecessary, but careful torque application is required

Proper mechanical integration ensures stable operation without excessive bearing load or encoder deformation, which is critical for long-term reliability.

Flange Types and Mounting Flexibility

Hollow-shaft SSI absolute encoders support multiple mounting configurations:

- Clamping flanges allow minor positional adjustments during installation

- Face flanges provide a fixed axial reference for high-precision applications

The choice of flange type directly affects repeatability, installation speed, and long-term mechanical stability, and should be considered alongside shaft diameter and available space.

Environmental and Operational Considerations

Hollow-shaft encoders are designed for conventional industrial environments:

- Moderate temperature and humidity ranges

- Indoor or enclosed installations

- Controlled exposure to dust and minor contaminants

While they simplify mechanical integration, they are not intended for hazardous, explosion-prone, or extreme-vibration applications. In such cases, explosion-proof or heavy-duty encoders are recommended.

Functional Characteristics

Hollow-shaft SSI absolute encoders provide:

- Deterministic absolute position feedback via SSI

- Immediate position availability after power-up

- Mechanical stability for direct shaft interface

Engineers should consider shaft diameter compatibility, encoder clamping method, and bearing load limits as critical factors affecting performance rather than solely focusing on maximum resolution.

Typical Applications

These encoders are commonly used in applications such as:

- Conveyors with existing shafts

- Rotating positioning axes in packaging or assembly machines

- Robotics joints or automation arms where direct shaft mounting reduces complexity

- Retrofit projects where shaft modifications are undesirable

Their primary advantage is mechanical simplicity and compact integration.

Retrofit and Replacement Considerations

When replacing a hollow-shaft encoder:

- Verify shaft diameter and axial space compatibility

- Ensure flange type matches mounting requirements

- Check that shaft tolerances meet alignment and concentricity needs

Using a mechanically compatible hollow-shaft encoder ensures minimal installation effort and maintains system precision.

When Hollow-Shaft Encoders Are Not Recommended

Hollow-shaft configurations are less suitable when:

- Extreme mechanical shock or vibration is present

- Direct installation in hazardous or explosive environments is required

- Very high torque or radial load exceeds bearing limits

In these scenarios, solid-shaft or explosion-proof designs provide better long-term reliability.

Engineering Summary

Hollow-shaft SSI absolute encoders are ideal for direct-shaft integration where space is limited and installation simplicity is critical.

Proper alignment, shaft interface selection, and flange choice are the primary determinants of performance, while standard industrial environmental conditions are fully supported.

Comments (0)