Engineering Background and Application Scope

PROFIBUS DP absolute encoders are widely applied in industrial automation systems where deterministic fieldbus communication and stable position feedback are required. Despite the increasing adoption of Industrial Ethernet, PROFIBUS DP remains deeply integrated in many production lines, machine tools, and material handling systems.

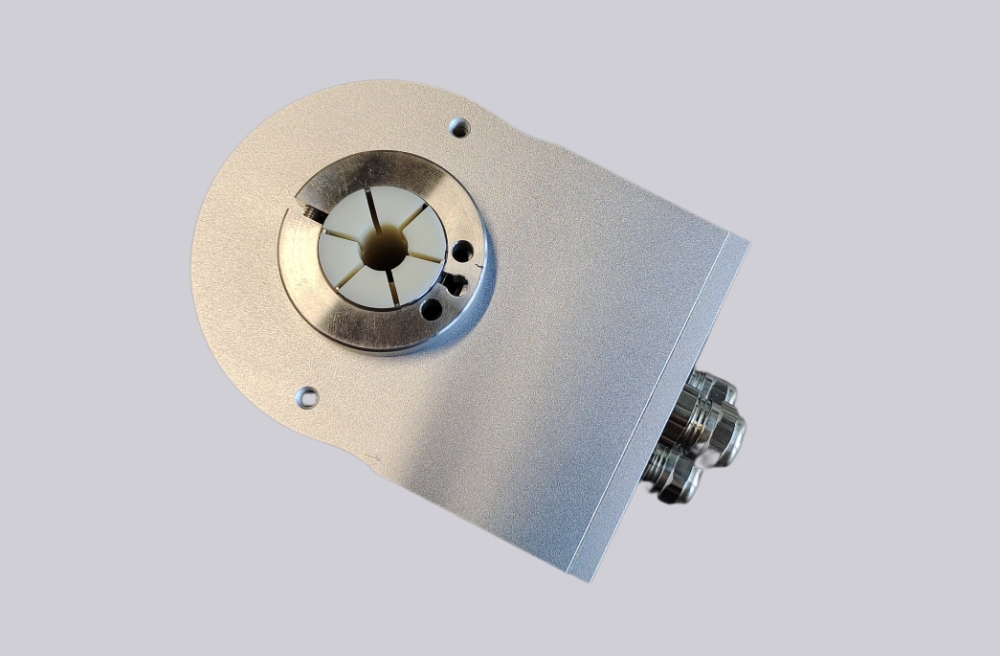

Standard-housing PROFIBUS DP absolute encoders are designed for general industrial environments, offering a balanced combination of mechanical adaptability, electrical stability, and proven fieldbus compatibility.

Mechanical Housing and Mounting Interfaces

Standard-housing designs focus on flexible mechanical integration while maintaining sufficient rigidity for long-term operation.

Typical mounting interfaces include:

- Clamp flange – suitable for applications requiring axial flexibility and precise alignment

- Blind hollow shaft flange – enabling direct shaft mounting with compact installation

These flange options allow engineers to adapt the encoder to different machine structures without altering the core feedback architecture. During selection, shaft diameter, mounting tolerance, and available axial space should be evaluated to ensure mechanical compatibility.

Absolute Position Feedback Characteristics

Absolute encoders provide position information immediately after power-up, eliminating the need for homing procedures. This is particularly beneficial in automation systems where restart accuracy and safety are critical.

In standard industrial applications, absolute position feedback supports:

- Repeatable positioning of machine axes

- Reliable recovery after power interruption

- Reduced commissioning and maintenance time

Single-turn and multi-turn configurations are commonly used depending on motion range and system requirements.

PROFIBUS DP Communication Integration

PROFIBUS DP is a deterministic fieldbus based on cyclic data exchange between a master (PLC) and slave devices such as encoders. PROFIBUS DP absolute encoders transmit position data and status information within defined bus cycles, ensuring predictable response times.

Key integration considerations include:

- PROFIBUS DP master compatibility

- Correct station addressing

- Proper bus termination and cable shielding

Stable network design is essential to maintain data integrity, especially in environments with electrical noise or multiple distributed nodes.

Environmental and Reliability Considerations

Standard-housing PROFIBUS DP absolute encoders are intended for non-hazardous industrial environments with controlled exposure to dust, vibration, and temperature variation.

To ensure long-term reliability, engineers should consider:

- Secure mechanical mounting to minimize vibration transmission

- Proper cable strain relief

- Grounding and shielding practices aligned with PROFIBUS guidelines

These measures help maintain both mechanical integrity and communication stability throughout the encoder’s service life.

Typical Industrial Applications

Standard-housing PROFIBUS DP absolute encoders are commonly used in:

- Conveyor and logistics systems

- Packaging and assembly machinery

- Automated production lines

- Machine tools with legacy or hybrid control architectures

In such systems, PROFIBUS DP remains a reliable and well-understood communication solution.

Engineering Selection Summary

From an engineering perspective, standard-housing PROFIBUS DP absolute encoders are well suited for applications requiring:

- Deterministic fieldbus communication

- Flexible mechanical mounting via clamp or blind hollow shaft flanges

- Reliable absolute position feedback for routine industrial automation

Correct selection depends on matching mechanical interfaces, communication requirements, and environmental conditions.

Engineering Reference

For detailed specifications and mechanical drawings, refer to the corresponding product documentation during final selection.

Reference:PROFIBUS-DP Absolute Encoder

Comments (0)