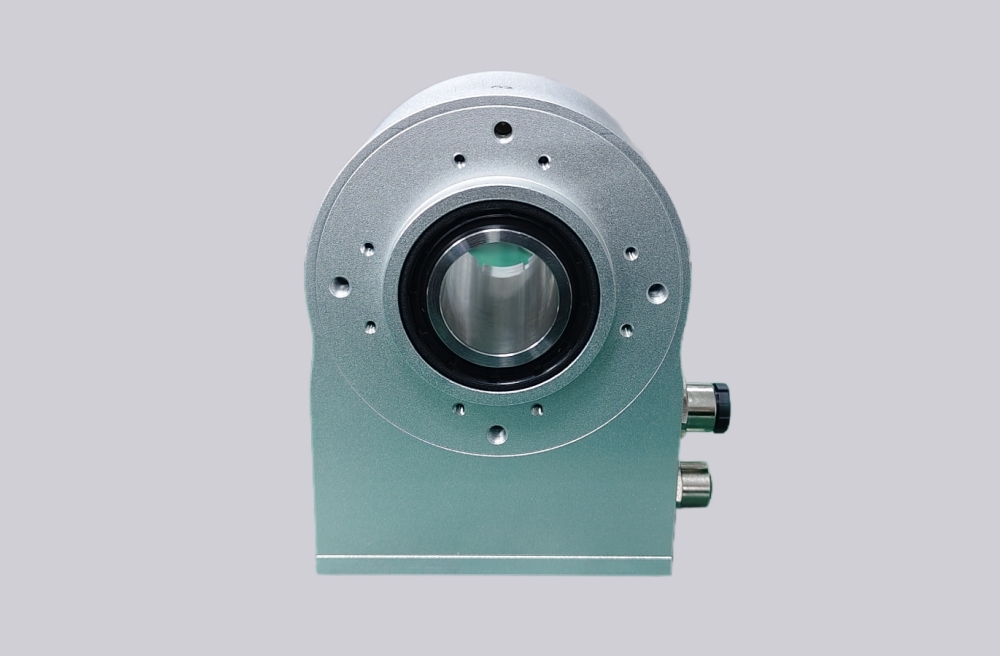

Role of Hollow Shaft Encoders in Modern Automation Systems

In industrial automation systems, hollow shaft absolute encoders are widely adopted for applications where direct mounting on rotating shafts is required. Compared with solid-shaft designs, hollow shaft encoders eliminate the need for additional couplings, reducing installation complexity and minimizing mechanical backlash.

When combined with PROFINET IO communication, hollow shaft absolute encoders provide both mechanical integration advantages and real-time Ethernet-based data exchange, making them particularly suitable for modern PLC-controlled automation systems.

Advantages of Hollow Shaft Design in Retrofit Projects

One of the most common use cases for hollow shaft PROFINET absolute encoders is retrofit and modernization projects. In existing machinery, replacing incremental encoders or outdated fieldbus devices often requires compatibility with existing shaft diameters and mounting interfaces.

Hollow shaft encoders allow direct installation onto the machine shaft without altering the original mechanical structure. This significantly reduces downtime during system upgrades and avoids the need for extensive mechanical redesign. For retrofit engineers, this flexibility is a decisive factor when upgrading legacy systems to PROFINET-based architectures.

Mechanical Alignment and Shaft Tolerance Considerations

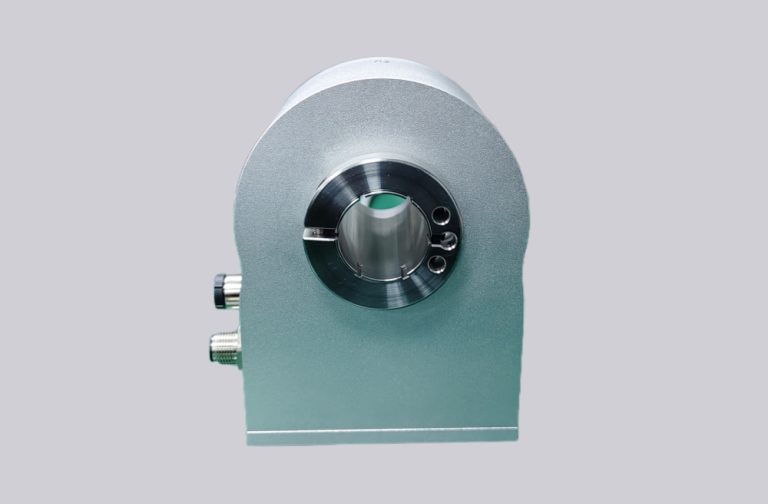

Although hollow shaft encoders simplify installation, mechanical alignment remains a critical engineering factor. Shaft concentricity, axial movement, and mounting tolerances directly affect encoder lifespan and measurement stability.

In high-duty industrial environments, improper alignment may lead to bearing stress, vibration-induced wear, or signal instability. Engineers must carefully evaluate shaft runout, mounting surface flatness, and fixation methods to ensure long-term reliability.

Anti-rotation mechanisms, such as torque arms or spring plates, are commonly used to prevent encoder housing rotation while allowing for slight shaft movement. Selecting the appropriate anti-rotation solution is essential, especially in applications involving thermal expansion or mechanical vibration.

Torque Transmission and Load Management

Torque transmission in hollow shaft encoders differs from solid shaft designs. Since torque is transferred directly from the machine shaft, excessive mechanical loads can affect encoder bearings and internal sensing components.

To mitigate this risk, proper shaft fit, correct clamping methods, and adherence to specified shaft tolerances are required. In applications with frequent acceleration, deceleration, or shock loads, engineers should evaluate whether additional mechanical damping or flexible mounting elements are necessary.

Understanding torque limits and load conditions during the design phase helps prevent premature encoder failure and ensures stable position feedback.

PROFINET IO Communication and System Integration

PROFINET IO enables cyclic real-time data exchange between hollow shaft absolute encoders and PLC systems, supporting deterministic control loops and advanced diagnostics. This communication capability allows seamless integration into modern automation networks without additional gateways.

From a system perspective, hollow shaft PROFINET encoders can be treated as standard PROFINET devices, enabling centralized parameterization, device identification, and status monitoring. This consistency simplifies commissioning and supports standardized maintenance procedures across different machine platforms.

Application Scenarios in Industrial Automation

Hollow shaft PROFINET IO absolute encoders are commonly used in applications such as:

- Conveyor and material handling systems

- Packaging and processing machinery

- Printing and paper handling equipment

- Automation retrofit projects replacing legacy encoders

In these scenarios, the combination of direct shaft mounting and Ethernet-based communication improves system responsiveness while maintaining mechanical simplicity.

Reliability and Long-Term Operation

Long-term reliability of hollow shaft encoders depends on both mechanical and electrical factors. Proper installation, controlled torque transmission, and stable network conditions are essential for consistent performance over extended operating cycles.

Regular inspection of mounting integrity and cable routing, combined with PROFINET diagnostic capabilities, helps identify potential issues before they lead to system downtime.

Engineering Selection Notes

When selecting hollow shaft PROFINET absolute encoders, engineers should carefully verify:

- Shaft diameter compatibility

- Mechanical tolerance and alignment requirements

- Anti-rotation method

- Network topology and communication constraints

Early evaluation of these factors ensures smooth integration and reliable operation throughout the system lifecycle.

Engineering Reference

For detailed specifications and mechanical drawings, refer to the corresponding product documentation during final selection.

Comments (0)