Engineering Background in Hazardous Environments

In hazardous industrial environments, position feedback devices are required to operate reliably under strict safety regulations while maintaining stable communication with higher-level automation systems. The combination of explosion protection requirements and real-time industrial Ethernet communication presents unique challenges for system designers.

PROFINET IO explosion-proof absolute encoders are developed to meet these challenges by integrating certified flameproof mechanical designs with deterministic Ethernet-based communication. They enable precise position feedback in environments where flammable gases, vapors, or combustible dust may be present, without compromising system performance or safety compliance.

Typical Applications and Industry Use Cases

Explosion-proof PROFINET IO absolute encoders are commonly applied in industries where hazardous area classifications are an inherent part of daily operation. Typical application fields include:

- Oil and gas production and processing facilities

- Chemical and petrochemical plants

- Offshore platforms and marine installations

- Bulk material handling and silo systems

- Mining and heavy industrial processes

In these applications, encoders are often installed on rotating equipment such as valves, winches, conveyors, and positioning mechanisms, where reliable absolute position information is critical for both operational control and safety monitoring.

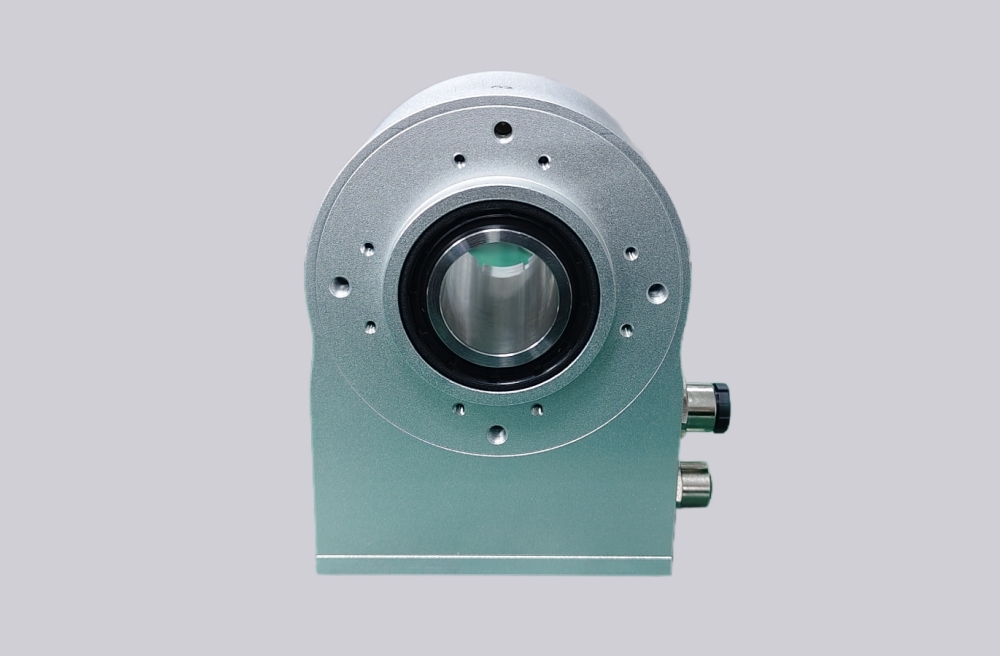

Explosion Protection Concepts and Mechanical Design

The defining characteristic of explosion-proof absolute encoders is their mechanical protection concept. Flameproof enclosures are engineered to contain any internal ignition and prevent flame propagation to the surrounding atmosphere. This design approach allows the encoder to operate safely in classified hazardous zones when installed and maintained according to applicable standards.

Compared with standard industrial encoders, explosion-proof designs typically feature reinforced housings, increased wall thickness, and carefully controlled cable entry systems. These mechanical considerations influence not only safety compliance but also installation planning, maintenance access, and overall system layout.

For engineers, understanding the mechanical implications of explosion protection is essential when selecting encoders for hazardous areas, as enclosure size, weight, and mounting requirements may differ significantly from standard devices.

PROFINET IO Communication in Hazardous Areas

PROFINET IO enables real-time Ethernet communication between field devices and PLC-based control systems, offering cyclic data exchange alongside advanced diagnostic and identification functions. In hazardous environments, this capability allows explosion-proof encoders to be integrated into standard PROFINET networks without protocol gateways or additional converters.

However, Ethernet-based communication in hazardous areas introduces specific engineering considerations. Network topology, cable routing, and connector selection must align with both PROFINET communication requirements and explosion protection standards. Proper segmentation between hazardous and non-hazardous zones is often required to ensure safe and reliable operation.

Despite these constraints, PROFINET IO provides significant advantages in terms of system transparency, diagnostics, and centralized monitoring, which are particularly valuable in large-scale industrial plants.

System Integration and Maintenance Strategy

In hazardous environments, maintenance access is often restricted, and unplanned downtime can carry significant operational and safety risks. Explosion-proof PROFINET absolute encoders support advanced diagnostic capabilities that enable condition monitoring and fault detection at the control system level.

By integrating encoders directly into the PROFINET network, engineers can access device status information, identify communication issues, and plan maintenance activities without frequent physical intervention. This contributes to improved system availability and safer maintenance workflows.

When planning system integration, engineers should consider long-term maintenance strategies, spare part availability, and compatibility with existing automation infrastructure.

Environmental and Reliability Considerations

Explosion-proof encoders are designed to operate under harsh industrial conditions, including temperature variations, vibration, and exposure to aggressive substances. Nevertheless, long-term reliability depends on correct installation practices, appropriate cable management, and adherence to specified environmental limits.

Special attention should be given to grounding, shielding, and mechanical alignment, as these factors directly affect both communication stability and mechanical lifespan. In Ethernet-based systems, maintaining signal integrity is particularly important in electrically noisy industrial environments.

Common Engineering Challenges and Selection Notes

Several recurring challenges are observed when implementing explosion-proof PROFINET encoders:

- Underestimating the impact of enclosure size on installation space

- Treating explosion-proof encoders as direct replacements for standard devices without mechanical review

- Overlooking network design constraints in hazardous zones

Addressing these factors early in the design phase helps prevent costly redesigns and ensures compliance with safety and communication requirements.

Engineering Next Steps

After defining hazardous area classification, communication protocol, and installation constraints, engineers should proceed with detailed verification of mechanical interfaces, electrical connections, and network architecture during final system design.

Engineering Reference

For detailed specifications and mechanical drawings, refer to the corresponding product documentation during final selection.

Reference: Explosion-Proof PROFINET IO Absolute Encoder

Comments (0)