Engineering Background for Hazardous-Area Applications

In industrial sectors such as oil and gas, chemical processing, mining, and energy production, equipment is often installed in environments where flammable gases, vapors, or combustible dust may be present. In these hazardous areas, position feedback devices must satisfy both functional control requirements and strict safety regulations.

Explosion-proof PROFIBUS DP absolute encoders are engineered to provide reliable absolute position feedback while complying with hazardous-area installation principles. Their design focuses on preventing ignition risks without compromising deterministic fieldbus communication.

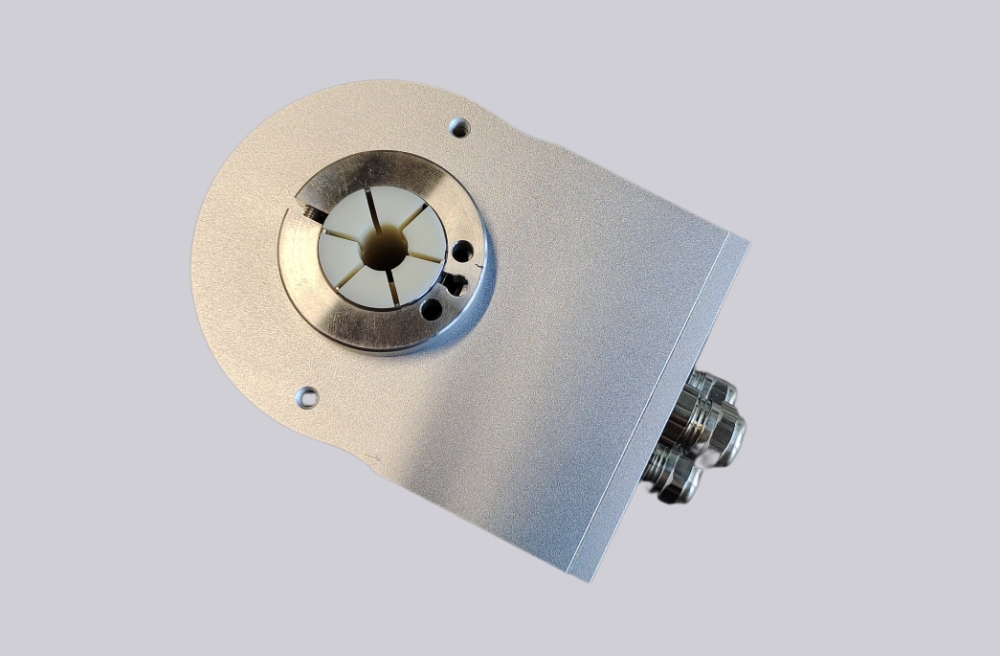

Explosion-Proof Housing and Mechanical Design

Unlike standard industrial encoders, explosion-proof designs rely on reinforced housings capable of containing internal ignition and preventing flame propagation to the surrounding environment.

From a mechanical perspective, these encoders typically feature:

- Reinforced metal housings with increased wall thickness

- Certified sealing structures for cable entries

- Robust mounting interfaces designed for long-term mechanical stability

Available mounting interfaces generally include:

- Clamp flange – allowing controlled axial positioning and secure mounting

- Blind hollow shaft flange – enabling direct shaft installation with compact mechanical layout

Mechanical rigidity and correct mounting are essential, as any unintended movement may affect both safety compliance and measurement stability.

Absolute Position Feedback in Safety-Critical Systems

Absolute position feedback plays a key role in hazardous-area machinery, where uncontrolled motion or incorrect positioning may lead to safety risks during startup or power recovery.

Explosion-proof absolute encoders enable:

- Immediate position availability after power restoration

- Elimination of homing procedures in restricted environments

- Predictable machine behavior during emergency stops or restarts

Single-turn or multi-turn configurations are selected based on motion range and process requirements, always with safety considerations in mind.

PROFIBUS DP Communication in Hazardous Environments

Despite the enhanced mechanical protection, communication remains based on standard PROFIBUS DP fieldbus principles. The encoder operates as a PROFIBUS DP slave, exchanging cyclic position data and diagnostic information with the master controller.

Key engineering considerations include:

- PROFIBUS DP master compatibility and configuration

- Stable bus topology with correct termination

- Proper shielding and grounding to minimize electromagnetic interference

In hazardous areas, communication diagnostics are especially valuable, as they provide early indication of abnormal operating conditions without requiring physical inspection.

Environmental and Reliability Considerations

Hazardous-area installations often involve extended temperature ranges, vibration, and exposure to aggressive atmospheres. Explosion-proof PROFIBUS DP absolute encoders are therefore designed for long-term operational stability under demanding conditions.

Engineers should account for:

- Secure mechanical mounting to avoid micro-movement

- Certified cable glands and sealed connections

- Controlled routing of PROFIBUS cables to maintain signal integrity

Correct installation directly influences both safety compliance and service life.

Typical Hazardous-Area Applications

Explosion-proof PROFIBUS DP absolute encoders are commonly applied in:

- Petrochemical and chemical processing plants

- Oil and gas production facilities

- Mining and bulk material handling systems

- Energy generation and heavy industrial installations

In these applications, PROFIBUS DP continues to provide reliable deterministic communication within established control architectures.

Engineering Selection Summary

From an engineering selection perspective, explosion-proof PROFIBUS DP absolute encoders are suitable for applications requiring:

- Compliance with hazardous-area safety requirements

- Deterministic PROFIBUS DP communication

- Robust mechanical design with clamp or blind hollow shaft flanges

- Reliable absolute position feedback in safety-critical systems

Careful evaluation of environmental classification, mechanical interface, and network design is essential for correct selection.

Engineering Reference

For detailed specifications and mechanical drawings, refer to the corresponding product documentation during final selection.

Comments (0)